3 times easy to use !

3 times light force !

3 times less effort !

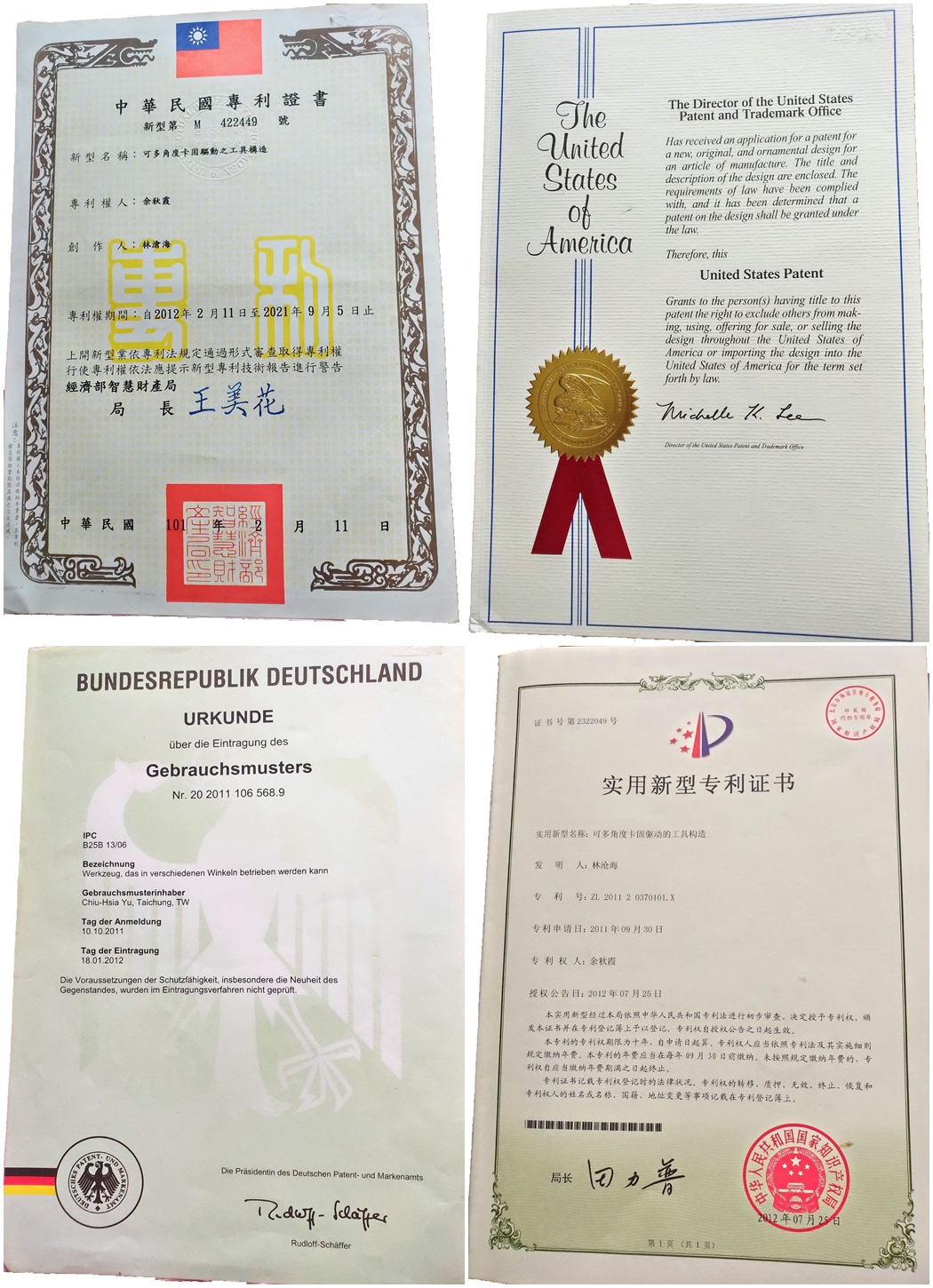

According to test data as follows:

In comparison between the patent granted 12-corner wrench socket and the traditional 4-corner wrench socket, the ratio of 12 corners to 4 corners equals 3. Accordingly, a 4-corner tool head of an electric tool may have a chance to be inserted into the 12-corner wrench socket as three times as a chance to be inserted into the 4-corner wrench socket. Furthermore, it is relatively laborious for a four-corner tool head of a manual wrench or electric tool to be inserted into the traditional 4-corner wrench socket. The patent granted 12-corner wrench socket has twelve corners and thus can disperse force as three times as the 4-corner wrench socket.”

Click here to see the catalog and view product information.

The patent granted screw sleeve arranged with a 12-corner wrench socket can allow a 4-corner tool head of an electric tool to be directly inserted thereinto without any trial. Thus, they are easy to be used. Compared with the traditional screw sleeve arranged with a 4-corner wrench socket, which allows a 4-corner tool head of an electric tool to be inserted thereinto with two or three times trials. Thus, they are not convenient to be used.

A 21-cm long-type F-bar drive wrench is provided with a tool head that can be inserted at 30 degrees into the patent granted screw sleeve arranged with a 12-corner wrench socket. They can be used in a narrow space in a faster, smoother and easier fashion. Compared with a traditional screw sleeve arranged with a 4-corner wrench socket, a wrench has a tool head that must be inserted at a vertical angle of 90 degrees into the traditional screw sleeve arranged with a 4-corner wrench socket, and thus they are not convenient to be used in a small space.

Detection: The patent granted 12-corner wrench socket meets the DIN gauge standard and also conforms to the gauge for the traditional 4-angle wrench socket. Thus, the patent may be used for the traditional 4-corner wrench.